Introduction

In engineering, materials are exposed to different types of loads. The loads that materials can be subjected to can be listed as tensile, compression, bending, shearing, or twisting. At the same time, these loads can differ statically or dynamically. The material may have to resist one or more of these loads at the same time. In this case, it is necessary to know which material to use under which conditions. In order to group materials, their reactions under certain loads are observed with tests, and the mechanical properties of the materials are thus revealed.

Mechanical characterization of materials at small length scales – Maria F. Pantano, Horacio D. Espinosa and Leonardo Pagnotta

We can separate the tests for obtaining elasticity properties into static and dynamic. For a test to be static, the force must be applied at a maximum frequency of 1 Hz, at a constant and one time only. In this case, the stress is constant and the elongation ratio is less than 0.25 in the static test. Dynamic tests are used for these types of loads since static tests cannot form an adequate model for suddenly changing loads. In dynamic testing, the load is variable and a sinusoidal deformation is applied to the sample. These tests can also be performed at high or low temperatures. As a result of dynamic tests, hardness and damping information are obtained. We can examine fatigue tests as a sub-branch of dynamic tests. The load is applied cyclically. These tests are performed with tensile-pull, compression-compression, or compression-reverse tensile cycles. As a result of the fatigue test, the life of the materials can be determined. Fatigue strength and cracking resistance are also determined with the fatigue test.

Tensile Test

Tensile testing is one of the most common tests in engineering to determine the strength properties of materials. It is done to determine the mechanical properties of isotropic materials. This test is basically based on the application of a tensile force on the specimen from opposite faces in the same direction, and monitoring the stress on the material until the material breaks. As a result of the tensile test, yield strength, maximum tensile strength, ductility, Young’s modulus, shear modulus and Poisson’s ratio of the material can be obtained.

Stress – Strain Curves

Stress and Strain Curves

The nominal tensile stress applied to the material during testing is as follows:

Where F is the tensile force and the A_0 is the cross-sectional area under tension. And the strain is defined as;

Where L_0 is the initial length of the speciemen and Δ_L is the elongation of the material after the test.

With the values derived from the test, the stress-strain curve is obtained. This curve reveals the material’s breaking point, yield strength, maximum tensile strength, and brittleness-ductility condition. Another benefit is that it gives information regardless of the material’s dimensions.

J. R. Davis – Tensile Testing (2004)

The diagram above shows the stress-strain curve of a brittle material.

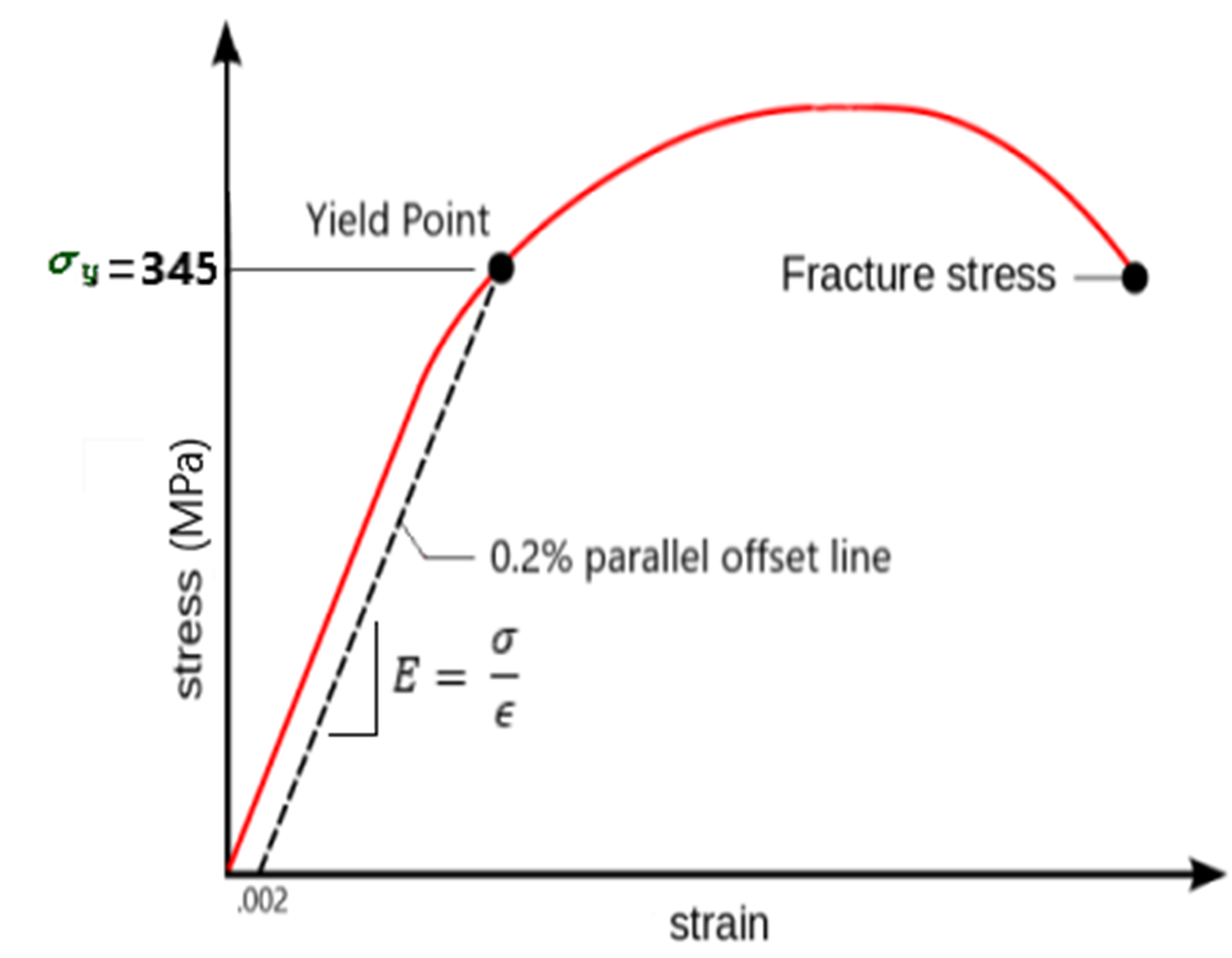

For most curves, the initial part is linear. The yield strength value is obtained on the curve when a curve parallel to the slope of the curve is drawn from the point where the elongation in the stress-strain curve is 0.2%. We can determine the maximum stress a material can withstand without permanent damage using its yield strength. Up to this point, the object is in the elastic region. After this, the material enters the plastic area, where the forces placed on it cause permanent damage.

Yield Stress

The slope of the imaginary line we draw to find the yield strength gives us the Young’s modulus, which is an important material property. Young’s modulus is obtained by:

The following equation represents Poisson’s ratio, which is the negative of the ratio of horizontal displacement to vertical displacement:

Test

Most of the cross-sectional views of the specimens used in the tensile test are shown in the figure. Samples can be formed as a sheet or a cylinder.

Different clamping types may be used depending on various materials and measurement sensitivity levels. Each method of binding has advantages and disadvantages of its own.

Springer Handbook of Materials Measurement Methods-Springer (2006)

Tensile tests are carried out according to certain standards. The standards also differ according to the type of material. For example, tensile tests of plastic materials are performed according to the ISO 527-1 standard. For metallic material tests at room temperature, the ISO 6892-1 standard is used. Apart from these, some of the other standards for tensile tests are:

- ISO 6259-1 – Thermoplastics Pipes – Determination Of Tensile Properties

- ASTM D 638 – Tensile Test for Plastics

- ISO 4136 -Destructive tests on welds in metallic materials — Transverse tensile test

- TS ISO 37, ASTM D 412, DIN 53504 – Standard Test Methods For Vulcanized Rubber And Thermoplastic Elastomers-Tension

- ISO 6892-2 – Metallic Materials – Tensile Testing – Part 2: Method Of Test At Elevated Temperature

Compression Test

The compression test demonstrates how materials behave when compressed or crushed. The test typically lasts until the substance breaks down or until a predetermined limit. The load that the material can withstand before tearing and the extent of its degradation up to this point are thus calculated. In order to test a material, it is often heated or cooled and subjected to many directions of compressive force. However, tests can be performed under varied settings.

Materials with high tensile strength generally have low compressive strength. For this reason, these materials are examined by compression testing. The materials on which the most compression tests are performed are generally brittle materials, for example, composites, concrete, wood, metal, and brick materials; polymers, plastics, and foams.

A force-strain curve is obtained as a result of the compression test. The force is then converted to stress to create a stress-strain curve. This curve is very similar to the stress-strain curve in the tensile test. Only the axes are in the direction to show the shortening.

Compression Stress – % Compression Deformation

The calculations in the tensile test are also valid for the compression test. compressive stres is expressed as;

Crushing

Crushing is used to express how much the material was shortened during the test.

Express the crushing.

Swelling

Swelling is the growth in the cross section of the material being tested. Ductile materials are more prone to swelling. It is formalized by:

Test

Brittle materials are typically the subject of compression tests. The compression characteristics of stiff foams are provided by ISO 844 as an example from the standards. The cross-sectional area values and forms, temperature-humidity values, and anticipated sample outcomes are stated in this standard. In kPa, the stresses are stated.

The compression elasticity value in the standard is as follows:

Here, σ_e, is the force at the end of the conventional elastic region, h_0 is the initial thickness of the material, and x_e is the path taken by the force generating the stress.

The following are a few of the standards developed for compression tests:

- ASTM D575-91 – Standard Test Methods For Rubber Properties In Compression

- ASTM E9-19 – Standard Test Methods Of Compression Testing Of Metallic Materials At Room Temperature

- TS EN ISO 14126 – Fibre-reinforced plastic composites — Determination of compressive properties in the in-plane direction

Fatigue Test

Regional, permanent and progressive material damages are caused by fatigue.

The basic logic in fatigue testing is the periodic application of relatively small varying forces to the material that will not cause permanent damage when applied a few times. In this way, materials are tested until cracks occur. The lifetime of the samples is determined by the fatigue test. The number of cycles the material encounters up to the point where it breaks gives us its fatigue life.

Stress-cycle graphs can be used to represent the results of the fatigue test. The maximum stress that can be applied decreases as the number of cycles in the fatigue test increases.

The cyclic stress applied during the test oscillates between the minimum and maximum values. Applied cyclic stress ratio is expressed as,

Load Cycle Graph

The level of applied stress affects how the material responds during a fatigue test. The number of cycles rises as the load quantity decreases. In high-cycle fatigue tests, the number of cycles is greater than and the applied stress remains in the elastic region. Tests with high cycles are load-controlled. On the other side, low-cycle fatigue tests feature significant stress and little elongation. The experiments are being conducted in a stretch-controlled manner.

Test

As previously mentioned, it is possible to remain in the elastic or plastic region during fatigue tests. According to the expected performance of the material, a fatigue test is run.

The curves for the fatigue test conducted on the hot-mix asphalt material, using the stress-strain curves, are as follows:

A strain-controlled hot-mix asphalt fatigue model considering low and high cycles P.J. Yooa and I.L. Al-Qadib

Here we see that the hardness of the material decreases with the increase of the cycle.

The following list includes some test standards for fatigue testing:

- ISO 12110-1 – Metallic materials – Fatigue testing (Variable amplitude)

- ASTM D7791 – Standard Test Method For Uniaxial Fatigue Properties Of Plastics

- ASTM C1368 – Standard Test Method For Determination Of Slow Crack Growth Parameters Of Advanced Ceramics

References:

w3.bilecik.edu.tr/wp-content/uploads/sites/119/2016/12/Basma-Deneyi.pdf

www.instron.com/en/resources/test-types/compression-test

www.laryee.com/Applications/Test-Type/176.html?gclid=CjwKCAjwmJeYBhAwEiwAXlg0AXTezMYov3Y_jp_2ZexpDSwxf2rEulbSJIx3winm7wPN-CBdvF6LJBoCcbMQAvD_BwE

www.ametektest.com/learningzone/testtypes/compression-testing

www.twi-global.com/technical-knowledge/faqs/what-is-tensile-testing

www.testresources.net/applications/test-types/tensile-test/

researchoutreach.org/articles/dynamic-versus-static-evolving-mechanical-characterisation/

resources.perkinelmer.com/corporate/cmsresources/images/44-74546gde_introductiontodma.pdf

malzemetest.com/kategori117-yorulma-fatigue-testi-nedir-ve-nasil-yapilir.html

yasincapar.com/tr/mekanik-yorulma/

www.asminternational.org/documents/10192/1849770/05224G_Chapter14.pdf

www.wmtr.com/Low-Cycle_Fatigue_Testing.html

www.researchgate.net/publication/236340117_Mechanical_characterization_of_materials_at_small_length_scales

www.alsalab.com/alsalab-dc.php?test=ok&teknik_id

akademik.duzce.edu.tr/Content/Dokumanlar/ahmetipekci/Dosya/50b88c60-c2e8-413e-ace0-dfa66ab3455b.pdf

www.metaluzmani.com/basma-deneyi-nedir

www.asminternational.org/documents/10192/1849770/06156G_Sample.pdf/6202c5f3-9ae8-479b-a8bd-d2050d37d534

www.wmtr.com/What_Is_Fatigue_Testing.html

study.com/learn/lesson/what-is-yield-stress-formula.html