Introduction In engineering, materials are exposed to different types of loads. The loads that materials can be subjected to can be listed as tensile, compression, bending, shearing, or twisting. At the same time, these loads can differ statically or dynamically. The material may have to resist one or more of these loads at the same […]

The Development of the Plastics Industry in the World and in Turkiye

Plastic Plastics are synthetic or semi-synthetic polymer substances formed by carbon (C), hydrogen (H), nitrogen (N), oxygen (O), and other organic or inorganic substances. Plastics are solid at room temperature. They are easy to shape by mechanical or chemical means. The development of plastic started with the use of natural materials (gum, shellac, etc.) with […]

Quality Control Tests of Packaging Films

What is Packaging? Packaging is a material that keeps the product it contains clean, safe, and healthy while also facilitating storage and transportation by ensuring that it arrives at its destination. Packaging can be classified as sales packaging, group packaging, transport packaging, and consumer packaging. Packaging Films Plastic films are used in packaging production; they […]

What is Hydrostatic Internal Pressure Test?

Hydrostatics is the science that studies the behavior of liquids at rest. The pressure arising from the accelerations in these fluids is called hydrostatic pressure. It is a test to determine material strength and life by measuring the deformation caused by hydrastatic internal pressure in plastic or thermoplastic pipes such as Polypropylene (PP), Polyethylene (PE), […]

What is OIT Thermal Analysis Test?

What is Thermal Analysis? Thermal analysis is the measurement of the changes in the physical properties of the sample, such as melting point, dehydration point, isomer transition point, weight, conductivity, as a function of temperature and time, as a result of a controlled change in the temperature of the sample taken from a substance. Thermal […]

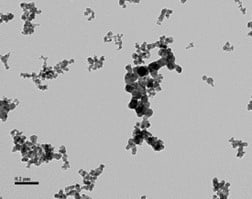

What Is Carbon Black Distribution?

What is Carbon Black? Carbon black is a pigment formed by the reaction of a hydrocarbon fuel, such as oil or gas, with a limited amount of combustion air at temperatures between 1320 and 1540 °C. It is a very fine, fluffy powder with a large surface area, consisting mainly of carbon. Although carbon black […]