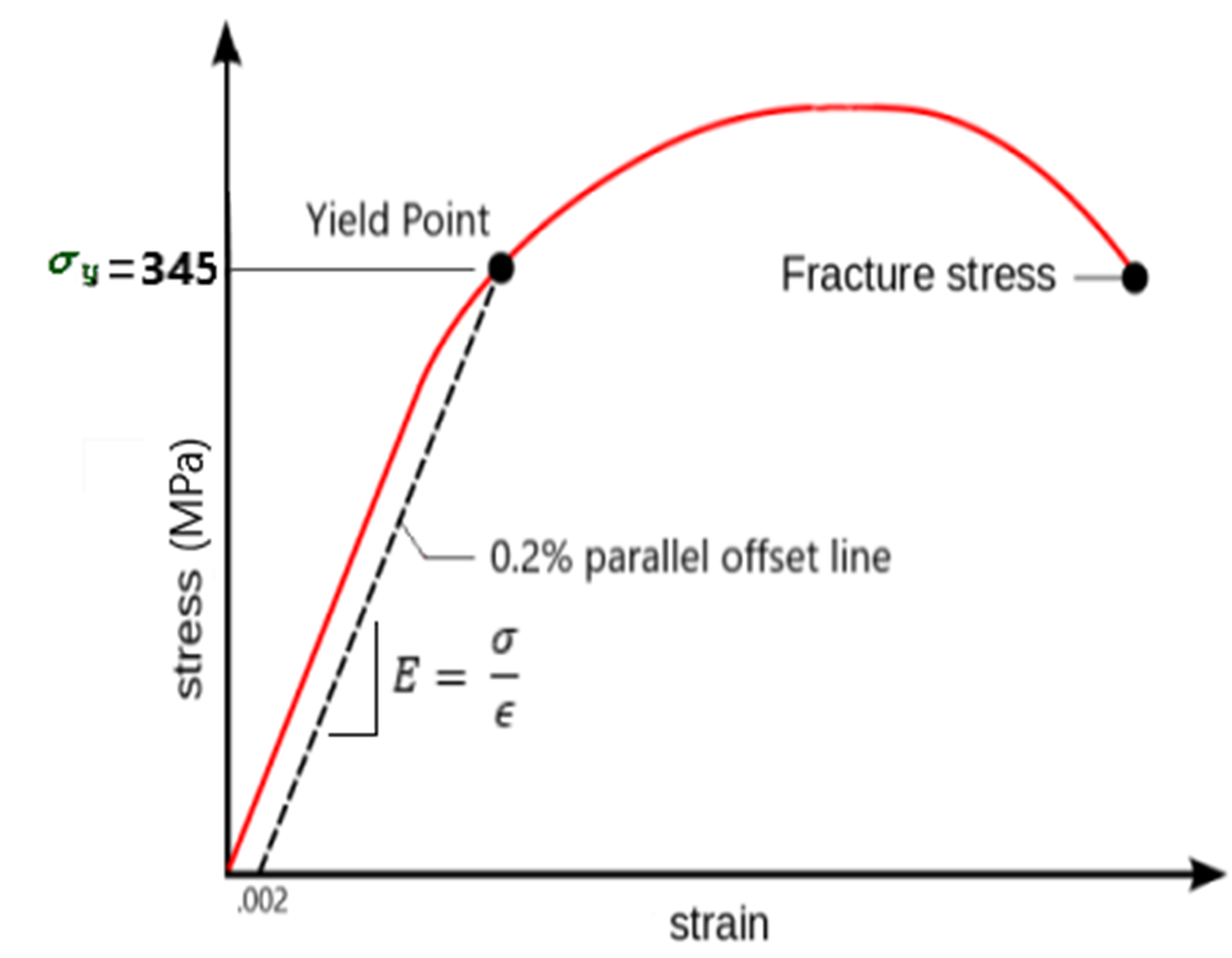

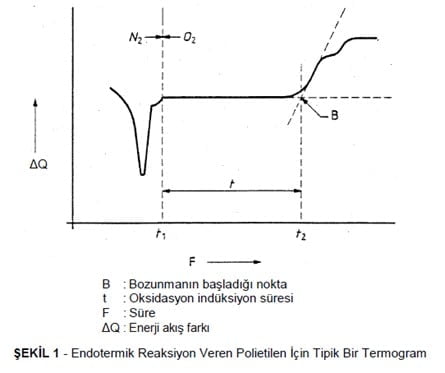

Tensile Test and Compression Test

Introduction In engineering, materials are exposed to different types of loads. The loads that materials can be subjected to can be listed as tensile, compression,

Anasayfa » Information Box

Introduction In engineering, materials are exposed to different types of loads. The loads that materials can be subjected to can be listed as tensile, compression,

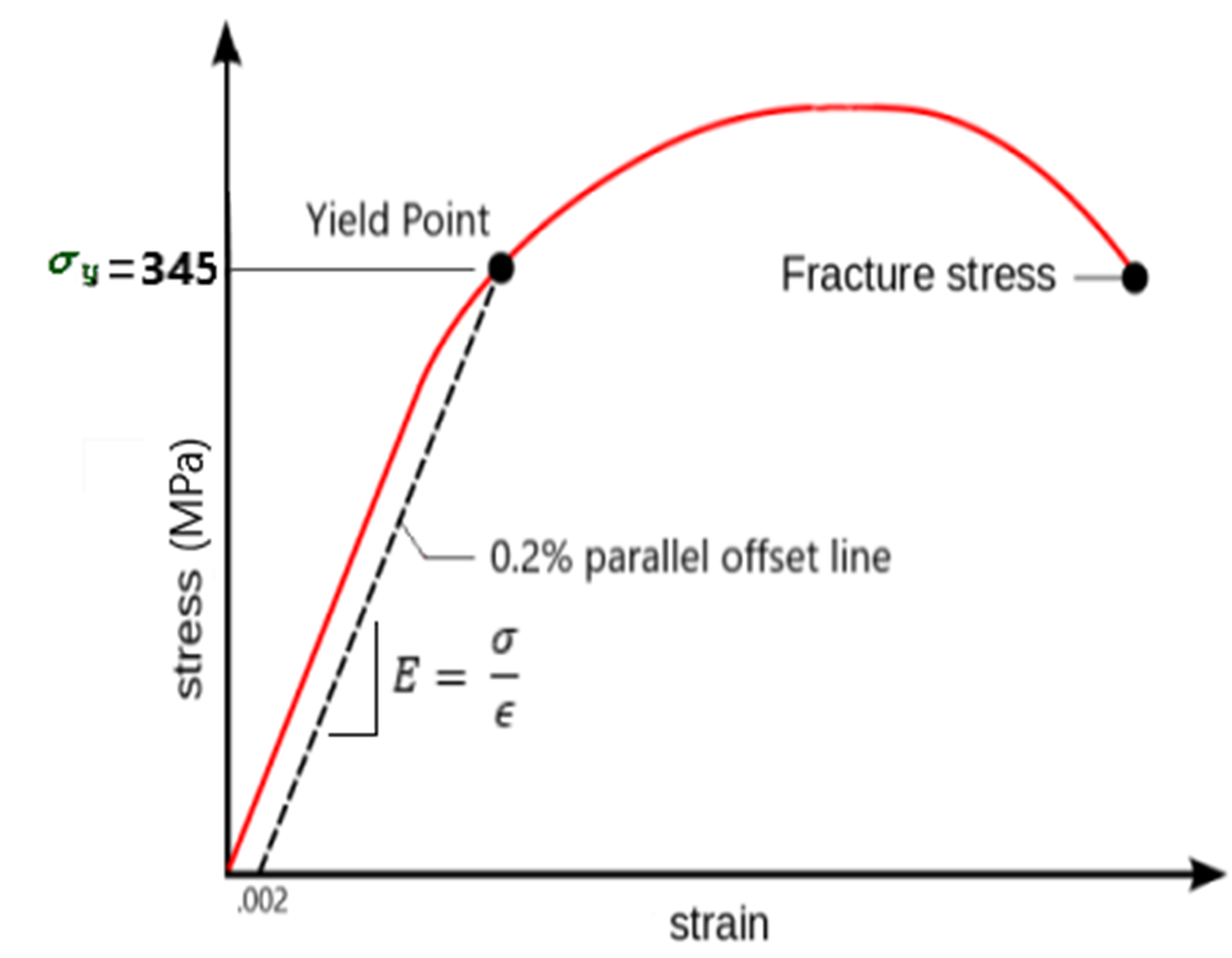

Plastic Plastics are synthetic or semi-synthetic polymer substances formed by carbon (C), hydrogen (H), nitrogen (N), oxygen (O), and other organic or inorganic substances. Plastics

What is Packaging? Packaging is a material that keeps the product it contains clean, safe, and healthy while also facilitating storage and transportation by ensuring

Hydrostatics is the science that studies the behavior of liquids at rest. The pressure arising from the accelerations in these fluids is called hydrostatic pressure.

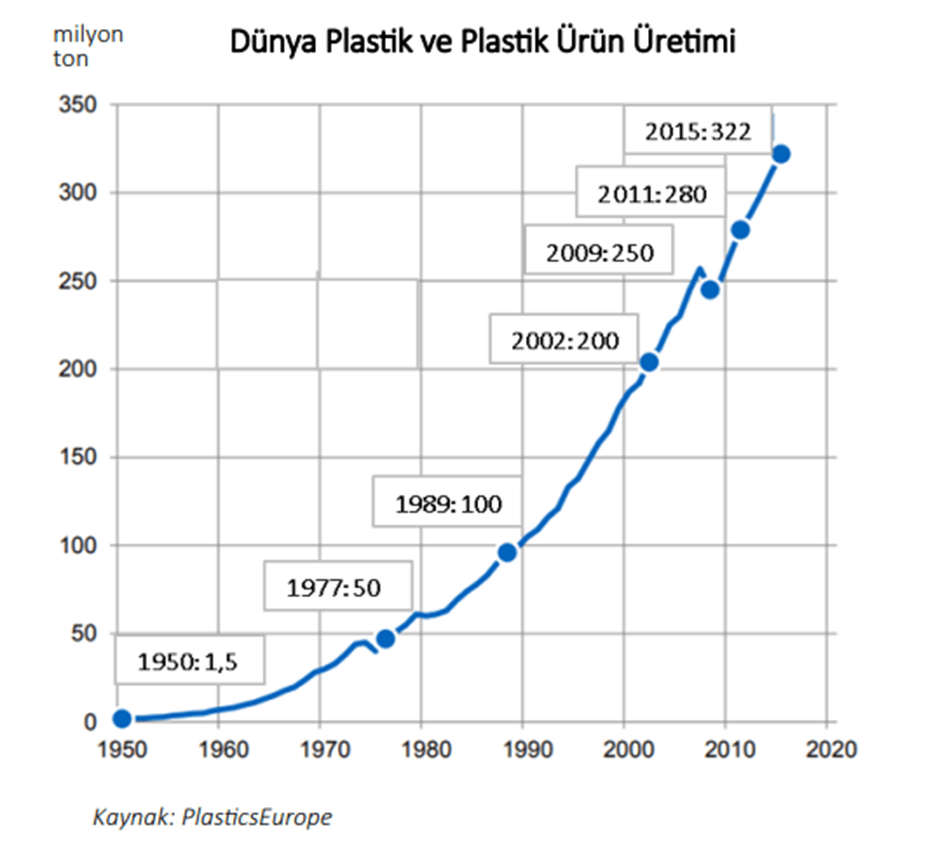

What is Thermal Analysis? Thermal analysis is the measurement of the changes in the physical properties of the sample, such as melting point, dehydration point,

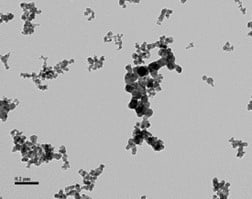

What is Carbon Black? Carbon black is a pigment formed by the reaction of a hydrocarbon fuel, such as oil or gas, with a limited

Support